Machine Proves The Perfect Fit

May 2015

|

Specification, performance, and price are some of the most common criteria for aluminium fabricators when they are buying new machinery, but size is not very often on the list of requirements.

However, when Hampshire based trade specialists Quick Glaze approached machinery specialists Emmegi (UK) to help them select a new machine to help them increase output of multi-fold doors, size was their top priority.

The company’s premises in Bordon is small so the company wanted a machine which would fit into the space available whilst at the same time delivering worthwhile improvements in capacity.

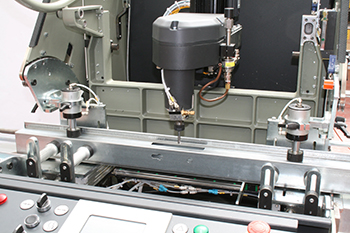

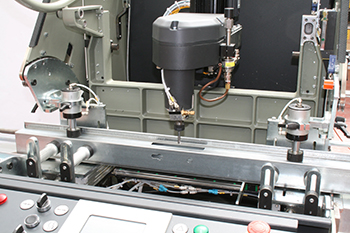

Emmegi’s sales manager Andrew Jones recommended Emmegi’s Nanomatic semi-automatic copy router with two controlled axes which fitted their requirements perfectly both in terms of dimensions and capability.

Martyn Quick, the managing director of Quick Glaze, was able to see the machine in action via the professionally produced videos on Emmegi’s website and was able to order a machine from stock at Emmegi’s UK headquarters in Coventry.

He said: “The whole buying process was simple and fuss free – the machine was the perfect size for our needs and now that it is up and running, it is proving even better than we expected.

“It has already helped us to double production of our Smarts multi-fold doors and has proved really versatile, more than meeting our machining requirements. Crucially, we now have the capacity to expand even further from our existing premises.”

The Nanomatic 384S machine can be connected to a PC via a USB connection and Emmegi’s intuitive software is easy to use. As a result, Quick Glaze are already reporting improvements in overall quality and consistent accuracy and have eliminated the potential for user error which existed with their previous manually operated copy router.

www.emmegi.com

www.quick-glaze.co.uk

|