The classes of Qualicoat

As sustainability issues continue to take precedence in material specification for new and refurbished buildings, Qualicoat continues to push the boundaries of quality and durability in architectural powder coatings.

As sustainability issues continue to take precedence in material specification for new and refurbished buildings, Qualicoat continues to push the boundaries of quality and durability in architectural powder coatings.

The powder coating process is widely used for coating various metals in domestic and commercial applications. In construction, the global Qualicoat ‘quality label’ is the number one choice for specifiers.

Finishing to the Qualicoat standard ensures a high quality, consistent finish to aluminium profiles and sheet-based products. Life expectancy can be warrantied up to 30 years and life expectancy can be much longer. Powder coating companies who meet the minimum requirements for pre-treatment and powder coating equipment can join Qualicoat and become a recognised holder of the coveted Qualicoat label.

‘Qualicoat UK and Ireland’ currently has 25 members in the UK who meet on a frequent basis to work together to further the understanding of powder coating and the high quality and consistency that the label offers. Qualicoat completes the supply chain to finished product by offering licences to powder manufacturers and metal pre-treatment suppliers as well as powder coat applicators to ensure consistent quality.

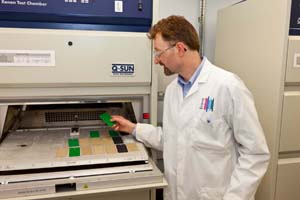

One of the quality management measures required by Qualicoat is twice yearly random visits by an independent test house to review a companies own quality procedures and records.

What is little known is that powders themselves can be supplied in various grades of durability to suit a project’s application. These premium powder compositions use more expensive and robust materials to offer life expectancies well beyond 30 years and often similar to the life expectancy of the building itself.

The vast majority of powder coating undertaken in the UK and Ireland from Qualicoat members and independent powder coaters meet what is known under the Qualicoat Specification (12th edition) as ‘class 1’. These powders are high quality and offer excellent weathering and life expectancy, however, there are projects and situations where even higher durability coatings are required by the specifier.

Using ‘Qualicoat’ powder coating the method of pre-treatment and powder coat application is tightly monitored and the chances of coatings failing due to corrosion or adhesion during its expected life are virtually eliminated. All powder coatings, however, will age over time and using higher durability powders will ensure that the surface finish looks better for longer. Higher durability powders can be used on high rise applications, or other places where access could be difficult or where there is a particularly harsh environment.

Powders for architectural coatings fall into three basic classes; Class 1 is a one-year ‘Florida’ weather exposure category; Class 2 is a three-year ‘Florida’ weather exposure category; and Class 3 is a 10-year ‘Florida’ weather exposure category.

In class 1 the samples tested must retain at least 50% of its original gloss level at the end of the test, whereas for class 2 powders they must retain at least 75% and class 3 powders at least 90% over the same period of exposure. Colour variation over time is similarly more stringent on classes 2 and 3.

As a specifier, should higher durability finishes be required, contact a Qualicoat member and discuss the project requirements in greater in detail. Pretreatment and powder application is virtually the same for classes 2 and 3, the only change is the formulation of the powder which uses enhanced resin systems and higher grade pigments and stabilisers.

The Qualicoat organisation, located in Zurich, continue to co-ordinate the method of application and the various county working groups to ensure that the Qualicoat label remains the number one choice for specifiers. A specification for Qualicoat by a UK specifier will be fully understood and implemented in various countries across the globe, irrespective of the lack of local standards.

Current news and information on architectural powder coating is frequently updated on the Qualicoat UK and Ireland website at www.qualicoatuki.org. The European website offers the complete specification which can be found at www.qualicoat.net. Printed literature and telephone support is available from Qualicoat UK & Ireland’s Head Office in Birmingham on 0121 601 6746.