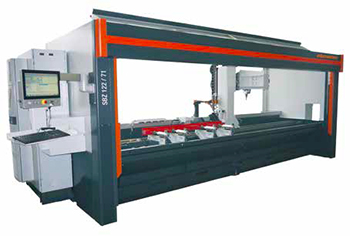

Next Generation Machining Centre Unveiled

January 2016

|

The launch of elumatec’s new SBZ 122 family of models sees a leap forward in machine design and engineering. The new models have lower space and energy requirements and can be adapted to suit customers’ differing needs and budgets thanks to their modular design.

Originally, the SBZ 122 was aimed at small to medium sized aluminium fabrication companies however because of its reliability and breadth of machining options it soon became established in other sectors including UPVC and steel. Companies ranging from small fabricators producing 20 windows a week to those manufacturing products in volume on a multi-shift operation bought these, and their budgets varied as widely as their application requirements.

With six models planned for the range the new SBZ 122 family of machines can be better tailored to suit these individual needs. Fabricators of UPVC products - especially doors - are very keen on the option to operate parallel machining which the SBZ 122 can handle perfectly as it can work the stationary profile bar, including inserted steel reinforcement, with an angle head from five sides in a single operation.

Other advantages of the new SBZ 122 generation include a larger work area with minimized installation space requirements; faster, more energy-efficient drives and narrower, more stable clamps.

The bed is dimensioned for high rates of travel with minimal oscillation. With dimensions of 300 x 300 mm, the machine’s work area has been enlarged while its overall footprint has become smaller. The protective enclosure reduces noise and eliminates the need for a light barrier meaning less space is required for installation.

Machining times have been reduced by 20 percent and the servo axes now operate at twice the previous speed. The X-axis achieves speeds of 120 m/min and the other two reach 60 m/min.

The increased rate allows the controller to react with more sensitivity and so enabling faster positioning of the spindles which are RPM regulated. Only the energy required for the machining task is supplied to the spindle, regardless of its rated power, and this results in energy savings of between 25 and 30 percent. Furthermore, the intelligent control technology ensures an extremely high degree of consistency in speed, which in turn produces very good machining quality even with quickly changing loading.

Maximum processing length is 4.15m without end processing or 4m with end processing. Travel distance of the X-axis is 4.2m and the Vmax. is 120 m/min; The Y-axis has a travel distance of 900 mm and a Vmax. of 80 m/min and the travel distance of the Z-axis is 610 mm, with a Vmax. of 80 m/min. The milling spindle can operate at speeds of up to 24,000 rpm at a power output of 8 kW, S1 with feedback. The tool magazine has four positions a standard; additional tool magazines, with a total of up to 20 positions, can be installed as needed anywhere along the X-axis and up to two angle heads can also be accommodated.

The new SBZ 122’s machining head now moves on a 45° inclined machine bed. Swarf automatically falls off of the bed making it easier to clean and the operator can work more ergonomically as they can get closer to the machine table when positioning profiles. Another new feature on the SBZ 122/70 and SBZ 122/71 is the elimination of the operating cable as clamp activation via a remote control button.

As with all elumatec systems, the machine is controlled via the intuitive and easily understandable touch-screen ECI (elumatec customer interface) graphic display which is available in three different versions from entry-level to ‘Professional’. The display is now attached to the machine frame with height adjustability to again take ergonomic working into account.

Phil Heavey, managing director of elumatec UK said: “elumatec offers premium quality, German engineered machines fully supported by UK service. The new SBZ 122 family of models showcases our exceptional machine design and manufacturing capabilities.

“The SBZ 122/70 and SBZ 122/71 are available now with the third SBZ 122 model being launched at FENSTERBAU FRONTALE, which takes place in March 2016 in Nuremberg, Germany.

“These models will be on our stand at the FIT Show in April 2016 along with other working machine models.”

www.elumatec.com

|